PROTECTIVE RELAYS

A) Protective relays are used in conjunction with medium voltage circuit breaker (above 600 volts) to sense an

abnormality and cause the trouble to be isolated with minimum disturbance to the electrical system and with the least

damage to the equipment at fault. They have the accuracy and sophistication demanded by the protective

requirements of the primary feeder circuits and larger electrical equipment. Protective relays are designed to be

responsive to an abnormal excursion in current or power flow, etc., and with varying operating characters are

commercially available. Each relay application requires custom engineering to satisfy the parameters of its particular

intended function on the system.

B) The more common protective relay is of the electromechanical type. That is some mechanical element such as

an induction-disc and induction cylinder of magnetic plunger is caused to move in response to an abnormal change

in a parameter of the electrical system. The movement can cause on contact in the control circuit to operate tripping

the related circuit breaker. Protective relays should be acceptance tested prior to being placed in service and

periodically thereafter to insure reliable performance. In a normal industrial application, periodic testing should be

done at least once a year.

C) The various facts involved in testing protective relays can be listed as follows:

1. The technicians must understand the construction operation and testing of the particular relay.

2. The technicians manufacturers instruction bulletin, as identified on the name plate of the relay should be

available to him. (It should be noted that Southern Substation, Inc. technicians carry on their test truck every

bulletin printed on all relays).

3. The technicians should be given the settings to be applied to each particular relay and the test points. This

data is often furnished on a time current curve of the coordination study displaying the characteristics of the relay.

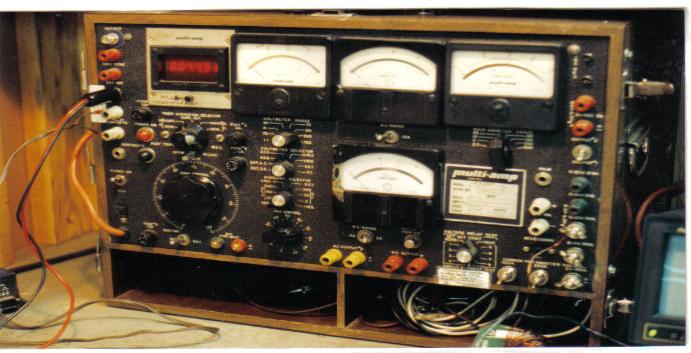

4. A test instrument, suitable to accurately accommodate the various acceptance and periodic maintenance tests

described in the manufacturers instruction manual, should be available. (It should be noted that Southern

Substation, Inc., technicians use only the SSI SR-95 relay test set. This is the most modern unit on the market and

is capable of firing an SCR Solid State Circuit).

5. Most protective relays can be isolated for testing while the electrical system is in normal operation. However,

an operation of the relays contacts will trigger the intended reaction, such as to trip the associated circuit breaker.

TESTING PROCEDURE

It is recommended that only one relay be removed from a circuit at a time if the circuit is still energized. Testing

and cleaning of relays are covered in each of the manufacturers instruction manuals. We have taken the best of

each of these manuals, plus data from two testing publications and formed the following procedure to be the best to

use:

A) Visual check and inspection of relay:

1. Remove the cover from the relay

a) inspect the cover gasket

b) check the glass for tightness in the frame, cracks, etc.

c) clean glass and covers inside and out.

2. Remove relay from case

a) short CT terminals for safety reasons

b) open all trip circuits

3. All foreign material such as dust or metal particles are removed from the relay and relay case. The

foreign material can cause trouble, particularly the air gap between the disc and magnet.

4. Dust particles are removed by gently blowing air from a small hand syringe.

5. Any rust or metal particles are removed from the disc or magnet poles with a magnet cleaner or brush.

6. Relay is put up to the light to make sure disc does not rub, and a good clearance exists between it and

the magnetic poles.

7. Relay is inspected for the presence of moisture. If free moisture exits, or rust spots are noted this

condition is pointed out to the owner. This condition may indicate that the relay is in the improper atmosphere

and could present a design problem.

8. All connections, especially taps, are checked for tightness. All screws, nuts and bolts that are not

pivotal joints are checked for tightness.

9. Sluggish bearings are detected by noting the smoothness of the relay reset. This is checked by rotating

the disc manually to close the contacts and observing that the operation is smooth, allowing the action of the spiral

spring to return the disc to its normal de-energized position. If the bearings appear to be bad or the operation of

the relay is questionable, this condition is then reported to the owner. If simple cleaning and oiling does not

remedy the problem, the relay should be removed from service and replaced by a spare. If the relay is new and

this problem is found on an acceptance test, this relay should be returned to the manufacturers. If this condition is

found during a maintenance test, the relay can be reconditioned by Southern Substation, Inc., technicians.

On plunger type relays, occasionally a burr a groove may develop causing the relay to hang up. All plungers are

given a very thorough inspection to assure that this has not occurred.

10. Mechanical operation of the targets are checked manually by fitting the armatures and observing a

showing of the target.

11. Relay coil are checked to assure that they have not been subjected to high currents for prolonged

period of time.

12. All relay components that touch when the relay is in a "normal" position and part as the relay

"operates" are cleaned. If these parts become dirty, they can cause the relay to stick and not operate properly

on relatively low current faults.

13. All pitted and/or burned contacts are cleaned and burnished with an approved contact burnishing tool.

B) Electrical Testing

a) Testing with the relay disconnected from the power and trip circuits. This method is standard yearly

maintenance type.

b) Testing across the secondary of the current transformer with the primary de-energized. This is called

secondary injection.

1a) This method is used

2b) This test includes checking the operation of the circuit breaker, presence of energy to trip breaker.

3c) This method is done by introducing the current voltage at the secondary terminals of instrument

transformer. This test, checks the relay connections as well as the relay.

C) Primary Circuit Test -High Current / Low Current (Primary injection)

This test is recommended on new or rebuilt equipment. This also requires total shut-down of both primary and

secondary voltage.

1. Complete system is checked, including the current transformer.

2. This test simultaneously checks current transformers, ratio, secondary wiring, polarity, relay operation and

identity of each phase on the switchboard.

3. This test is also valuable for initially checking buss differentials where many current transformers are

parallel at the relay.

D) Types of Testing

1. Insulation Resistance

2. Zero Check

3. Pick-Up (Induction disc. and/or instantaneous unit)

4. Time characteristics (when applicable)

5. Target and seal-in operation

6. Special test that are peculiar to the specific type of relay such as through fault, reach, dropout, etc.

Continue to Page two of Relay testing for more Information.